Log wagon

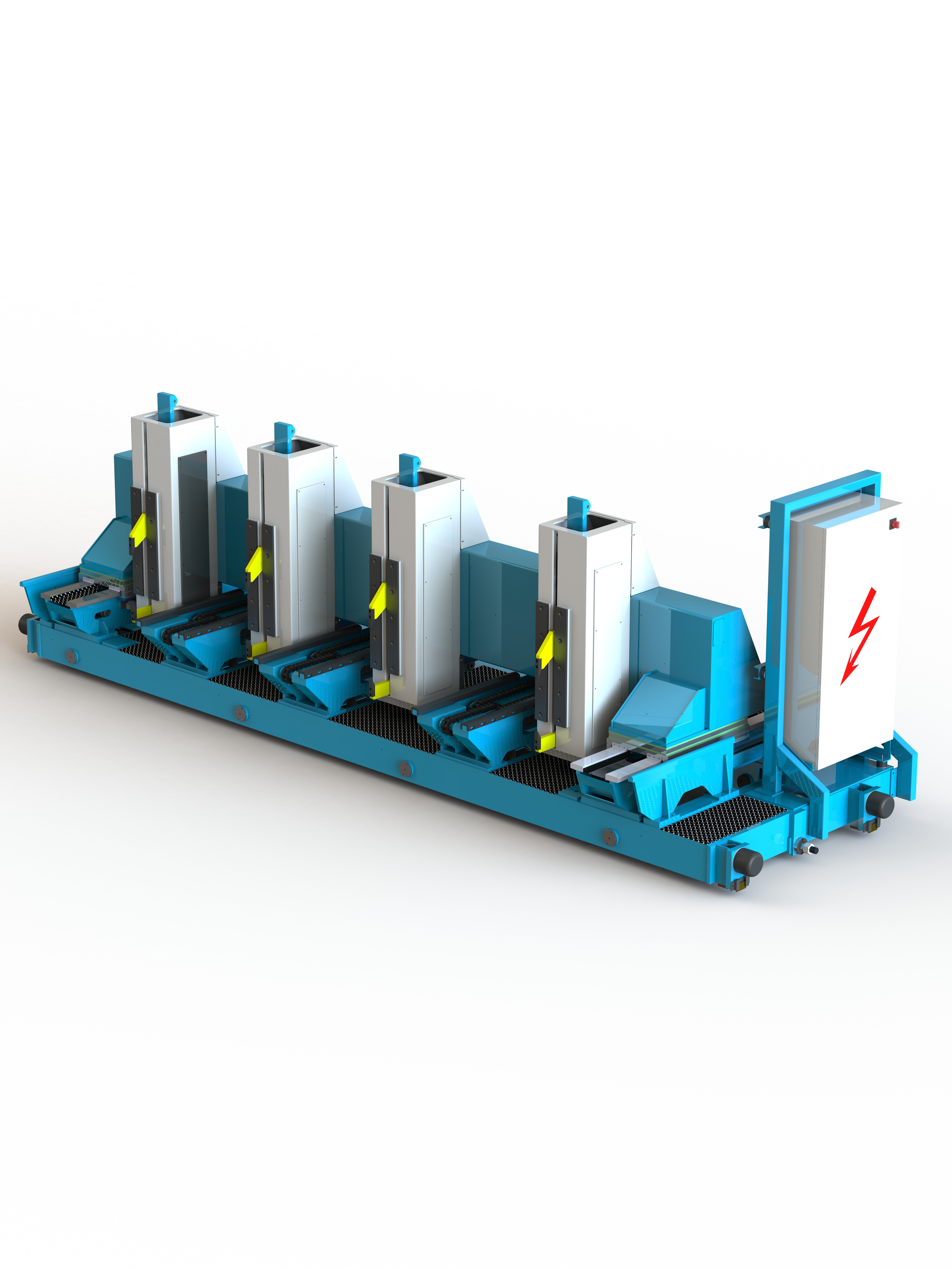

LOG WAGON CMOL-43

Technical characteristics :

The solid upper frame houses the vices and the hydraulic unit complete with motor and 11.00 kW variable displacement pump with heat exchanger.

The clamps are managed with a variable capacity pump with cylinders that allow a good reaction speed as the hydraulic system has been built with a dedicated line for opening and closing the jaws with three types of pressure, 40/80/150 and with the possibility for the operator to select the pressure and the harpoon position system automatically.

In and out of the harpoon, the position is managed and set by the operator, being retro-acted by a position transducer that allows the harpoon outfeed to be set at will. In the exclusion phase, the harpoon retracts completely into the clamp.

In the log machining phase, a harpoon retraction with gripped log is given the possibility of better log adhesion to the vises.

As always, we have an eye on accessibility in the event of maintenance needs; therefore the vices are provided with a carter for inspection and maintenance and both the harpoons and the log support plate against squares are removable and replaceable in the event of wear.

Hydraulic management is all in 24VDC low voltage.

We use an innovative system called IO-Link Field Bus that allows diagnostics of all sensors and actuators on the machine.

Technical configuration data:

- Frame length mm 6,900;

- N.4 clamps

- N.3 double-jointed turntables

- Track length quantified in 18 m;

- Complete with electric feed unit

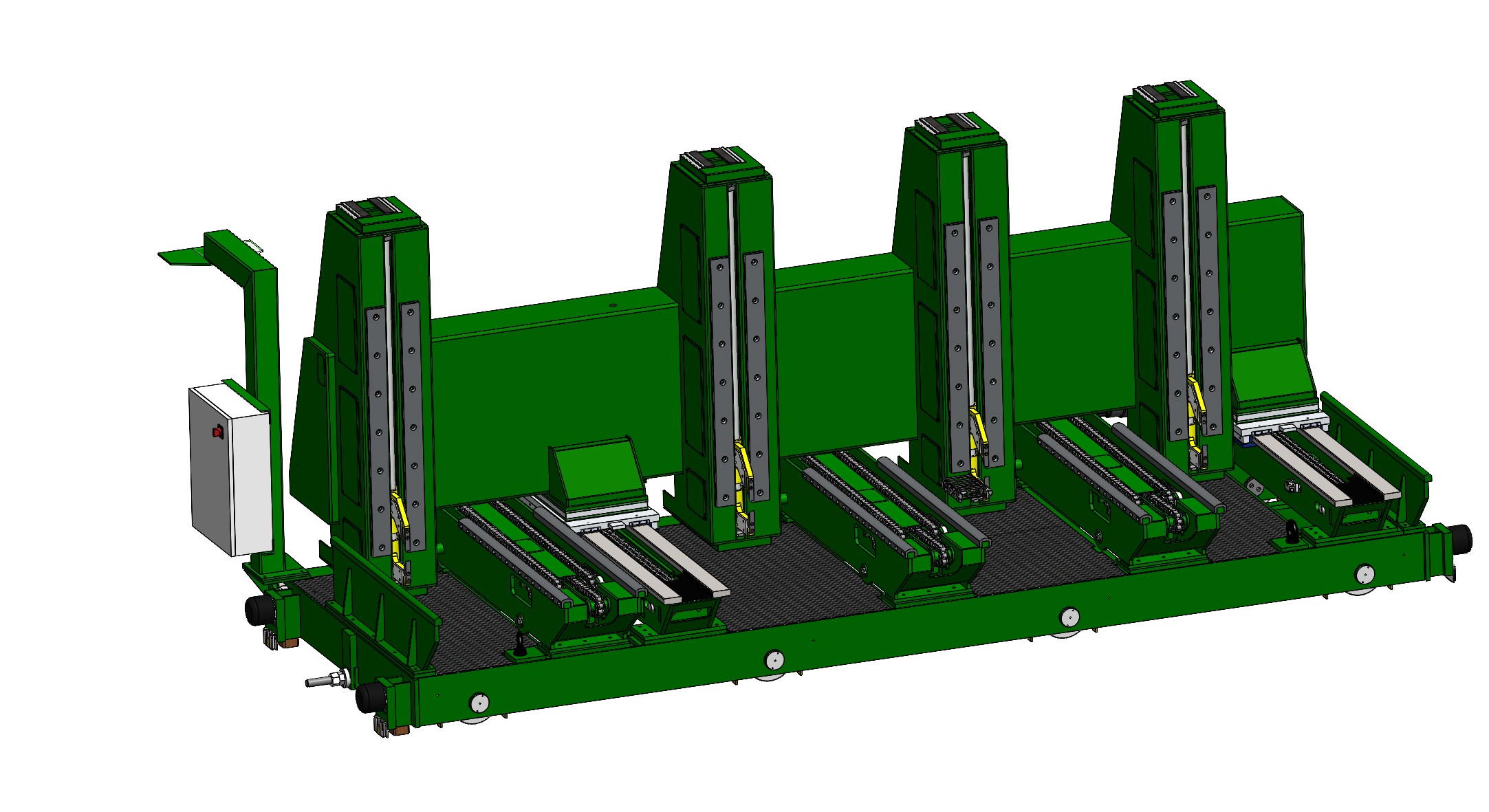

LOG WAGON CMOL.33

Technical characteristics :

The solid upper frame houses the vices and the hydraulic unit complete with motor and 11.00 kW variable displacement pump with heat exchanger.

The vices are managed with a variable capacity pump with cylinders that allow a good reaction speed as the hydraulic system has been built with a line dedicated to opening and closing the jaws with three types of pressure, 40/80/150 and with the possibility for the operator to select the pressure and the harpoon position system automatically.

In and out of the harpoon, the position is managed and set by the operator, being retro-acted by a position transducer that allows the harpoon outfeed to be set at will. In the exclusion phase, the harpoon retracts completely into the vice.

In the log machining phase, a harpoon retraction with gripped log is given the possibility of better log adhesion to the vises.

As always, we have an eye on accessibility in the event of maintenance needs; therefore the vices are provided with a carter for inspection and maintenance and both the harpoons and the log support plate against squares are removable and replaceable in the event of wear.

Hydraulic management is all in 24VDC low voltage.

We use an innovative system called IO-Link Field Bus that allows diagnostics of all sensors and actuators on the machine.

Technical configuration data:

- Frame length mm 6,900;

- N.3 vices

- N.3 double-jointed turntables

- Track length quantified in 18 m;

- Complete with electric feed unit

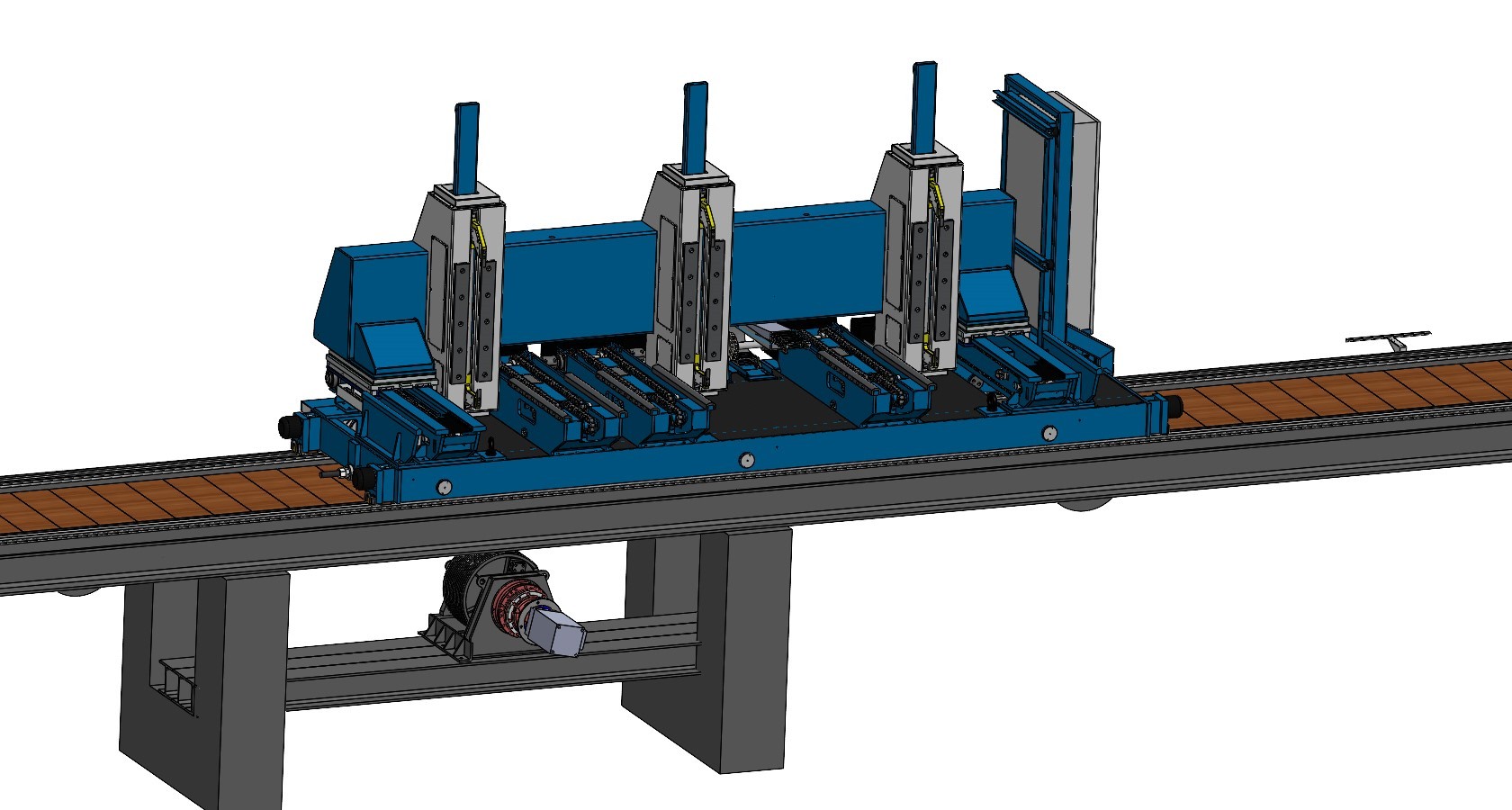

LOG WAGON CMOE-43

Technical characteristics :

The solid upper frame houses the vices and the hydraulic unit complete with motor and 11.00 kW variable displacement pump with heat exchanger.

The vices are managed with a variable capacity pump with cylinders that allow a good reaction speed as the hydraulic system has been built with a line dedicated to opening and closing the jaws with three types of pressure, 40/80/150 and with the possibility for the operator to select the pressure and the harpoon position system automatically.

In and out of the harpoon, the position is managed and set by the operator, being retro-acted by a position transducer that allows the harpoon outfeed to be set at will. In the exclusion phase, the harpoon retracts completely into the vice.

In the log machining phase, a harpoon retraction with gripped log is given the possibility of better log adhesion to the vises.

As always, we have an eye on accessibility in the event of maintenance needs; therefore the vices are provided with a carter for inspection and maintenance and both the harpoons and the log support plate against squares are removable and replaceable in the event of wear.

Hydraulic management is all in 24VDC low voltage.

We use an innovative system called IO-Link Field Bus that allows diagnostics of all sensors and actuators on the machine.

Technical configuration data:

- Frame length mm 6,620;

- N.4 vices, hook opening mm 1500, vice opening mm 1600

- N.3 double-articulated log turners

- Length of track quantified in mt 18;

- Complete with electric feed unit

"BRENTA" HEAVY LOG CARRIER FOR EXOTIC LOGS

- Wagon with n. 4 heavy type electric clamps with electric gripping;

- Track distance 1,400 mm, wagon length 6,500 mm;

- Maximum blade opening: 1,400 mm;

- Maximum opening of the harpoon on carriage guides 1.400 mm;

- Horizontal translation of the harpoons motorized with electric motors;

- Heavy structure with n. 6 axles and turned wheels with mechanical shift to levers disinseribile;

- Rack-and-pinion drive assembly and self-braking drive motor with double brake (new) 7.5 HP;

- Thickness determination system with original BRENTA divider;

- Heavy-duty towing unit with BOHERINGHER hydraulic drive and reducer;

- Towing drum, associated gear wheels and pulleys;

- Well-finished and repainted tracks; track length 21 m;

- Control console with original divider "BRENTA" (perfect);

- Control panel and console to be controlled;

- Excluding on-board electrical system.

LOG CARRIER "BONGIOANNI" TO ELECTRIC MORSE

Opportunity! Revised.

Consisting of:

- Wagon with n. 3 electric clamps with new screws and nuts (gripping control);

- Completely repainted (internally and externally);

- Wagon length 5,000 mm, wagon width 1,180 mm;

- No 4 axle track centre 950 mm;

- Current distance between jaws 1,200-2,000;

- Screw drive unit with new bronze screws and nuts (thickness determination);

- Self-braking morse translation motor;

- Cable towing unit with hydraulic variator and gearbox;

- Perfect towing drum with respective perfect pulleys;

- Control console with original "Bongioanni" electrosynchronous divider (perfect) and built-in control lever with mechanical shift system;

- Electrical system on board wagon in each vice (group teleinvertitori perfect).